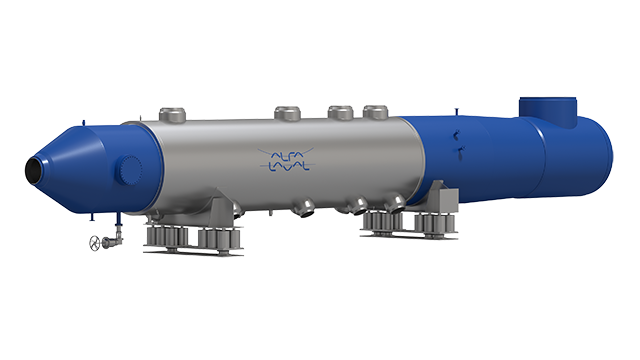

工藝管殼式換熱器

阿法拉伐Olmi工藝管殼式換熱器專為最苛刻的應用而設計,用于石油化工廠、煉油廠、石油和天然氣生產設施以及發電站的苛刻位置。憑借最優的材料、先進的焊接和卓越的工藝技術,這些耐用可靠的管殼式換熱器幾乎可以應對任何挑戰。

About Alfa Laval Olmi

Having produced heat exchangers for high temperature and high-pressure applications for more than 80 years, we know how to design, manufacture, commission and service your next heat exchanger for maximum efficiency and reliability.

Each Alfa Laval Olmi heat exchanger is custom made and draws on the full body of application knowledge that we have built over the decades. We make sure your heat exchanger provides low costs, great performance and a long service life by optimizing it according to your specific requirements and operating conditions.

World-leading engineering expertise

With a full team of thermal and mechanical design experts on board, our engineering department can take on your most complex heat exchanger design challenges. Working together with our welding and manufacturing experts, they push the design

boundaries and come up with new, smart solutions that result in higher reliability and lower investment costs.

Our engineers can advise you on the best materials to use based on your operating conditions and process media. They help you find the materials that offer an optimum balance between CAPEX and OPEX by performing a total-cost-of-ownership analysis.

Welding – our core competence

The durability of a heat exchanger operating at extreme conditions is highly dependent on the quality of the welds. Even minor imperfections can cause breakdowns and costly service stops.

Our welding engineers and welding coordinators are all EWE and EWT certified. Our welders are all EN and ASME certified and are experts in welding exotic materials and joining dissimilar materials.

Testing

Testing

We perform rigorous pre-delivery testing on every heat exchanger that leaves our workshop. Our inspectors are certified to NDE Level II and III according to SNT TC1A and EN9712. We perform a range of non-destructive tests including ultrasonic NDE, X-ray and gamma ray tests, hydro tests, pressure tests using helium and dye penetrant tests.

For the toughest applications

Alfa Laval Olmi heat exchangers are used in some of the most demanding positions in petrochemical plants, refineries, oil and gas production facilities and power stations around the world. Year after year these process-critical units continue to deliver high performance and stable operation.

Petrochemical plants

- Quench coolers (TLEs, PQEs, SQEs, TQEs) for ethylene plants

- Urea strippers and carbamate condensers

- Process gas boilers for ammonia, methanol and syngas plants, including steam drums, superheaters and feed water pre-heaters

- High-pressure/high-temperature process shell-and-tube heat exchangers

- High-pressure/high-temperature process air cooled heat exchangers

- Melamine tubular reactors

Refineries

- Shell-and-tube heat exchangers for highpressure/high-temperature positions

- Feed-effluent interchangers for hydro processing plants

- Process gas boiler packages for hydrogen production

- Special heat exchangers for hydrogen production

- Air-cooled heat exchangers for reactors and column effluents

Oil and gas production

- Shell-and-tube heat exchangers for natural gas compression and oil treatment

Air cooled heat exchangers for:

- Natural gas compression cooling in enhanced oil recovery processes (onshore and offshore)

- Natural gas compression cooling in highpressure gas transmission (onshore)

Power stations

- Gas turbine once-through coolers

- Steam generator packages for thermal solar plants

- High-pressure feed water pre-heaters and steam drums

Our service offer

- Commissioning

- Troubleshooting

- Audits

- Repairs and reconditioning, including advanced welding and post-welding heat treatments

- Supervision, engineering and project management

- All types of testing (ultrasonic, X-ray and gamma ray, hydro, pressure, dye penetrant, etc.)

- Supply of material and spare parts

- Supply of equipment required for the service

- Training

Reliability at heart

Production faclities

- 65,000 m2 (700,000 sq ft) workshop

- 900 m2 (9,700 sq ft) cleanroom for assembly, welding and testing of non-ferrous, high alloy metal equipment. This prevents iron and dust contamination

- Precision drilling of tubesheets is performed in our CNC threespindle drilling machine

- Shot blasting, painting and flame metal coating facilities

- Ultrasonic test equipment

- Helium mass spectrometer equipment, magnetic particle die penetrant equipment