2016-08-30 產品新聞

Alfa Laval FlowSync is the energy-efficient way to more cat fine protection

Flow optimization of the separator feed increases protection from cat fines while decreasing energy use. The new Alfa Laval FlowSync is a single solution for automatic flow control, unique in its ability to steer multiple separator feeds simultaneously.

Alfa Laval FlowSync is an automatic control system that synchronizes the oil feed to Alfa Laval separators with the engine load. By matching the flow of fuel to the engine’s needs, it increases retention time in the separator bowl, giving the separators the best possible conditions for doing their job. As the only system of its kind that can steer multiple separator feeds simultaneously, FlowSync can optimize the entire fuel cleaning process for the best protection and energy efficiency.

“With FlowSync, Alfa Laval’s world-leading separators become an even stronger and more cost-effective defence against cat fines,” says Mats Englund, Application Manager, Fuel & Lube Oils at Alfa Laval.

Making slow steaming more efficient

To increase the effectiveness of centrifugal separation, which remains the best defence against cat fine attacks, FlowSync takes fuller advantage of slow steaming. While slow steaming today is beneficial overall, it makes ineffective use of the fuel system layout.

“Since most vessels use fixed-speed feed pumps, they experience a large overflow of separated fuel when slow steaming,” Englund explains. “At partial loads the unconsumed fuel is returned to the settling tank, only to be pumped and separated again. Unfortunately, the resulting improvement in cat fine content is negligible.”

When FlowSync is used, the fixed-speed pumps are replaced with variable-speed pumps. These are steered automatically by FlowSync, which matches their throughput to the engine load with an ample margin of safety. “Automatic control is integral to achieving full benefit from the investment,” says Englund. “Because the crew is not always alert to changes in engine load, manually controlled variable-speed pumps tend not to be adjusted.”

Reduced flow, increased separation efficiency

With FlowSync adjusting the separator feed rate, there is a very positive impact on separation efficiency. As the flow rate decreases, the fuel is allowed to spend more time in the separator bowl, which increases the separator’s ability to remove smaller and lighter particles. Though a properly operated separator removes nearly all cat fines larger than 10 μm, cat fines smaller than 3 μm are substantially more difficult.

“Increasing retention time in the bowl lets the separator remove the most stubborn particles,” says Englund. “Even the tiniest cat fines can cause significant wear and damage if they become trapped between the piston ring and cylinder liner.”

Two types of energy savings

For energy efficiency as well, FlowSync has major benefits. Because the feed rate is matched to the fuel consumption, there is minimal overflow from the day tank back to the settling tank – and no re-pumping of previously separated fuel. This in itself means energy saved.

A still greater amount is saved in the separator, where energy is used to accelerate the fuel, drive it through the disc stack and finally pump it out again. A separator consumes around 1 kWh per cubic metre of separated fuel, which means savings of 1 kWh for every cubic metre of reduction with FlowSync.

One system for all separator feeds

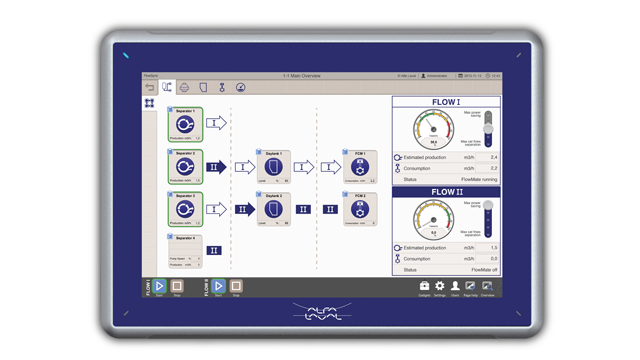

Unlike other flow optimization systems, FlowSync is a single control system for multiple feed pumps and the entire fuel flow. It allows optimization of the whole cleaning process, even when there are multiple lines of separators and tanks. Via the intuitive Alfa Laval Touch Control panel, users can choose to run more separators at reduced flow for maximum separation efficiency, or fewer separators at reduced flow for maximum energy savings.

“FlowSync is a triple win, combining increased separation efficiency with energy efficiency in pumping and separation,” says Englund. “But the biggest win is for ship owners and operators, who can achieve these benefits with a small investment and minimal effort from the crew.”

To learn more about Alfa Laval FlowSync and Alfa Laval’s approach to oil treatment and energy efficiency, visit www.alfalaval.com/marine

Editor’s notes

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx. 4.25 billion Euros). The company has about 17 500 employees.